ESO/F Carrasco

ESO/F CarrascoExcessive on a mountain, in Chile’s bone dry Atacama desert the European Southern Observatory (ESO) is at present constructing the world’s largest optical telescope.

No time was wasted on selecting a reputation – it is going to be known as the Extraordinarily Giant Telescope or ELT.

As a substitute, enormous power has gone into designing and constructing “the world’s greatest eye on the sky”, which ought to begin accumulating pictures in 2028 and could be very prone to increase our understanding of the universe.

None of that will be doable with out among the most superior mirrors ever made.

Florent Mallet/Mersen Boostec

Florent Mallet/Mersen BoostecDr Elise Vernet is an adaptive optics specialist at ESO and has been overseeing growth of the 5 large mirrors that may collect and channel mild to the telescope’s measuring tools.

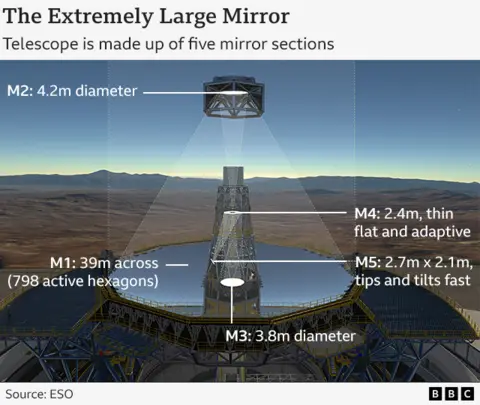

Every of the ELT’s customized mirrors is a feat of optical design.

Dr Vernet describes the 14ft (4.25m) convex M2 mirror as “a chunk of artwork”.

However maybe the M1 and M4 mirrors finest specific the extent of intricacy and precision required.

The first mirror, M1, is the most important mirror ever made for an optical telescope.

“It’s 39m [128ft] in diameter, made up of [798] hexagonal mirror segments, aligned in order that it behaves as an ideal monolithic mirror,” says Dr Vernet.

M1 will gather 100 million occasions extra mild than the human eye and should be capable to keep place and form to a stage of precision 10,000 occasions finer than a human hair.

The M4 is the most important deformable mirror ever made and can be capable to change form 1,000 occasions per second to appropriate for atmospheric turbulence and the vibrations of the telescope itself that might in any other case distort imagery.

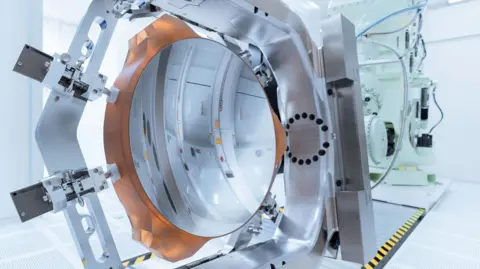

Its versatile floor is made up of six petals of a glass-ceramic materials that’s lower than 2mm (0.075in) thick.

The petals have been made by Schott in Mainz, Germany after which shipped to engineering agency Safran Reosc simply exterior Paris, the place they have been polished and assembled into the whole mirror.

All 5 mirrors are nearing completion and can quickly be transported to Chile for set up.

Whereas these huge mirrors might be used to seize the sunshine of the cosmos, ESO’s neighbours in Garching, on the Max Planck Institute for Quantum Optics, have created a quantum mirror to function on the tiniest scales possible.

In 2020, a analysis staff was capable of make a single layer of 200 aligned atoms behave collectively to mirror mild, successfully making a mirror so small it can’t be seen by the bare eye.

In 2023, they succeeded in putting a single microscopically managed atom on the centre of the array to create a “quantum change” that can be utilized to regulate whether or not the atoms are clear or reflective.

“What theorists predicted, and we noticed this experimentally, is that in these ordered buildings, when you soak up a photon and it will get re-emitted, it is truly emitted [in one predictable] route and that is what makes it a mirror,” says Dr Pascal Weckesser, a postdoctoral researcher on the institute.

This skill to regulate the route of atom-reflected mild may have future functions in plenty of quantum applied sciences like, for instance, hack-proof quantum networks for storing and transmitting data.

Zeiss

ZeissAdditional north-west in Oberkochen close to Stuttgart, mirrors with one other excessive property are being made by Zeiss.

The optics firm spent years creating an ultra-flat mirror which has turn into a key element within the machines which print laptop chips, known as excessive ultraviolet lithography machines, or EUVs.

Dutch firm ASML is the world’s main maker of EUVs, and Zeiss mirrors are an integral part of them.

Zeiss’s EUV mirrors can mirror mild at very small wavelengths which allows picture readability at a tiny scale, so an increasing number of transistors could be printed on the identical space of silicon wafer.

To clarify how flat the mirrors are, Dr Frank Rohmund, president of semiconductor manufacturing optics at Zeiss, makes use of a topographical analogy.

“When you took a family mirror and blew it as much as the scale of Germany, the very best elevation level can be 5m. On an area mirror [as in the James Webb Space Telescope], it might be 2cm [0.75in]. On an EUV mirror, it might be 0.1mm,” he explains.

This ultra-smooth mirror floor mixed with programs that management the mirror’s positioning, additionally made by Zeiss, yield an accuracy stage equal to bouncing mild off an EUV mirror on the Earth’s floor and selecting out a golf ball on the moon.

Whereas these mirrors could already sound excessive, Zeiss has plans for enchancment, to assist make much more highly effective laptop chips.

“We have now concepts about learn how to develop EUV additional. By 2030, the purpose is to have a microchip with one trillion transistors on it. As we speak, we’re possibly at 100 billion.”

That purpose got here nearer with Zeiss’s newest tech, which allows the printing of about thrice extra buildings on the identical space than the present technology of chip making machines.

“The semiconductor business has this dominating sturdy roadmap which supplies a drumbeat for all gamers contributing to the answer. With this, we’re capable of present progress when it comes to microchip fabrication which in the present day permits issues like synthetic intelligence which have been unthinkable even ten years in the past,” says Dr Rohmund.

What humanity will perceive and be able to in ten years’ time stays to be seen, however mirrors will little question be on the coronary heart of the applied sciences that take us there.